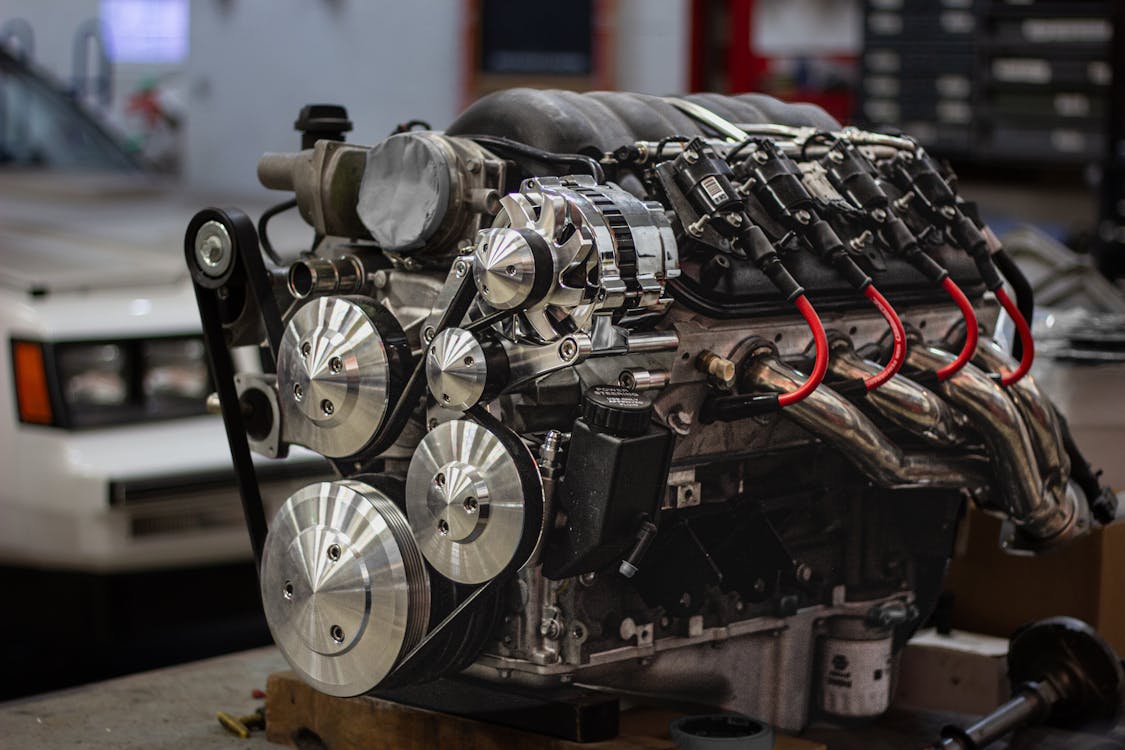

The car engine is the beating heart of every vehicle - a marvel of mechanical engineering that converts fuel into motion. Understanding how an engine works and what each component does can help you maintain your car better and diagnose issues early. Whether you are an automotive enthusiast or simply a curious car owner, knowing the key components of your engine and their functions can deepen your appreciation for this complex machine.

In this detailed guide, we’ll explore the main parts of a car engine, how they function, and how they work together to power your vehicle efficiently.

At its core, a car engine is designed to convert chemical energy (fuel) into mechanical energy (movement). This process takes place inside the combustion chamber, where a mixture of fuel and air ignites under pressure, generating a controlled explosion. The energy from that explosion moves the pistons, which then rotate the crankshaft, producing power that drives your car’s wheels.

This continuous process happens hundreds of times per minute, enabling your vehicle to accelerate, cruise, and idle smoothly.

The engine block is the foundation of the entire engine. Typically made of aluminum or cast iron, it houses several cylinders where the combustion process occurs. The block also accommodates other components such as pistons, crankshafts, and camshafts.

How It Works:

The engine block contains passages for coolant and oil to flow through, ensuring the engine remains cool and lubricated. It’s designed to withstand extreme temperatures and high pressure generated during combustion.

Maintenance Tip: Check for leaks and maintain proper coolant levels to prevent overheating and block damage.

Pistons are cylindrical components that move up and down within the cylinders. They play a critical role in transforming the energy from combustion into mechanical power. Each piston is attached to a connecting rod, which links it to the crankshaft.

How It Works:

When fuel ignites in the combustion chamber, the expanding gases push the piston down. This movement turns the crankshaft, converting linear motion into rotational energy that powers your car.

Maintenance Tip: Listen for knocking or rattling sounds, as these may indicate piston wear or damage. Proper lubrication prevents friction and piston scoring.

The crankshaft is one of the most important rotating components in the engine. It converts the up-and-down motion of the pistons into rotational motion that eventually turns your car’s wheels.

How It Works:

The crankshaft spins within the engine block and connects to the transmission system. It’s balanced with counterweights to ensure smooth rotation and minimize vibrations.

Maintenance Tip: Regular oil changes are crucial, as low oil levels can cause the crankshaft bearings to wear prematurely.

The connecting rods serve as the link between the pistons and the crankshaft. They transfer the linear motion of the piston into rotational motion through the crankshaft.

How It Works:

Each connecting rod has two ends - a small end attached to the piston pin and a big end connected to the crankshaft. The constant up-and-down motion puts tremendous stress on these rods, so they must be made from strong materials like forged steel or titanium.

Maintenance Tip: If you hear knocking sounds, it may indicate worn connecting rod bearings. Ignoring this issue can lead to engine failure.

The cylinder head sits atop the engine block, sealing the combustion chambers. It contains the valves, spark plugs, and sometimes fuel injectors in modern engines.

How It Works:

The cylinder head plays a critical role in airflow, sealing, and combustion. Intake valves let in air and fuel, while exhaust valves let out burnt gases. The spark plugs ignite the mixture, starting combustion.

Maintenance Tip: Watch for oil leaks or coolant mixing with oil - signs of a blown head gasket. Cleaning carbon deposits also helps maintain efficiency.

The valvetrain controls the flow of air and fuel into the engine and the expulsion of exhaust gases. It includes valves, the camshaft, and the timing belt or chain.

How It Works:

The camshaft rotates in sync with the crankshaft and pushes the valves open and closed at the right time. The timing belt or chain connects the two, ensuring precision in valve timing. Any misalignment can cause poor performance or even engine damage.

Maintenance Tip:

Replace your timing belt every 60,000–100,000 miles as recommended by your vehicle manufacturer to avoid catastrophic engine failure.

The spark plugs ignite the air-fuel mixture in gasoline engines. Each spark plug delivers an electric spark at the perfect moment during the combustion cycle. The ignition system, including ignition coils and wiring, powers the spark plugs.

How It Works:

When voltage passes through the spark plug, it jumps the small gap at the tip, igniting the compressed mixture in the cylinder. The resulting explosion pushes the piston downward.

Maintenance Tip: Replace spark plugs every 30,000–60,000 miles. Faulty spark plugs lead to misfires, poor fuel economy, and sluggish acceleration.

The fuel system ensures that the engine receives the correct amount of fuel mixed with air for combustion. It includes components like the fuel pump, fuel injectors, and fuel filter.

How It Works:

Fuel travels from the gas tank to the injectors through the fuel pump. The injectors spray a fine mist of fuel into the cylinders for efficient combustion.

Maintenance Tip: Clean or replace fuel injectors regularly and use quality fuel to prevent clogs that can reduce power and mileage.

Engines generate significant heat, so the cooling system keeps temperatures under control. It includes the radiator, water pump, thermostat, and coolant passages.

How It Works:

Coolant circulates through the engine block, absorbing heat. It then flows through the radiator, where it cools down before re-entering the system.

Maintenance Tip: Flush the coolant every two years to prevent rust and corrosion. Keep an eye on your temperature gauge to detect overheating early.

The lubrication system keeps moving parts coated with oil, reducing friction and wear. It consists of the oil pump, oil filter, and oil pan.

How It Works:

Oil is pumped through passages in the engine, coating components like the crankshaft and pistons. This not only reduces friction but also cools and cleans internal parts.

Maintenance Tip: Change your engine oil and oil filter regularly - typically every 5,000 to 7,500 miles, depending on the manufacturer’s recommendation.

The exhaust system removes the gases produced during combustion. It includes the exhaust manifold, catalytic converter, resonator, and muffler.

How It Works:

Exhaust gases exit the cylinders through the manifold and travel through the catalytic converter, which reduces harmful emissions. The muffler minimizes noise before gases are released through the tailpipe.

Maintenance Tip: If you hear loud noises or smell fumes inside the car, check for leaks or damage in the exhaust pipes.

Modern engines rely on various sensors and an Electronic Control Unit (ECU) to optimize performance. These sensors monitor oxygen levels, air intake, temperature, and more.

How It Works:

The ECU uses data from these sensors to adjust fuel delivery, ignition timing, and emissions control for maximum efficiency.

Maintenance Tip: Check engine lights often signal sensor issues. Use an OBD-II scanner to identify faulty sensors and replace them as needed.

Every component in a car engine plays a vital role in making your vehicle run efficiently. From the pistons and crankshaft to the sensors and ECU, these parts work in perfect harmony to produce power and keep your car moving. Regular maintenance and awareness of each part’s function can help extend your engine’s lifespan and prevent costly repairs.

By understanding your engine’s main components and how they work, you’re not just a driver - you’re a more informed vehicle owner capable of keeping your car performing at its best.

A car engine typically has dozens of parts, but the key ones include the engine block, pistons, crankshaft, valves, spark plugs, and cylinder head.

Engine failure often results from overheating, lack of oil, poor maintenance, or ignoring warning signs like knocking noises or oil leaks.

With regular maintenance, most modern engines can last between 150,000 and 250,000 miles, sometimes even longer.

The cylinder head or the crankshaft is often among the most expensive components to repair or replace due to labor and complexity.

Simple maintenance like oil changes or replacing spark plugs can be DIY tasks, but complex issues such as timing belt replacement should be done by professionals.